Value-added Services

JSD always strive to provide our customers with the best possible options that meet their requirements and minimize any potential production delays or disruptions.

JSD always strive to provide our customers with the best possible options that meet their requirements and minimize any potential production delays or disruptions.

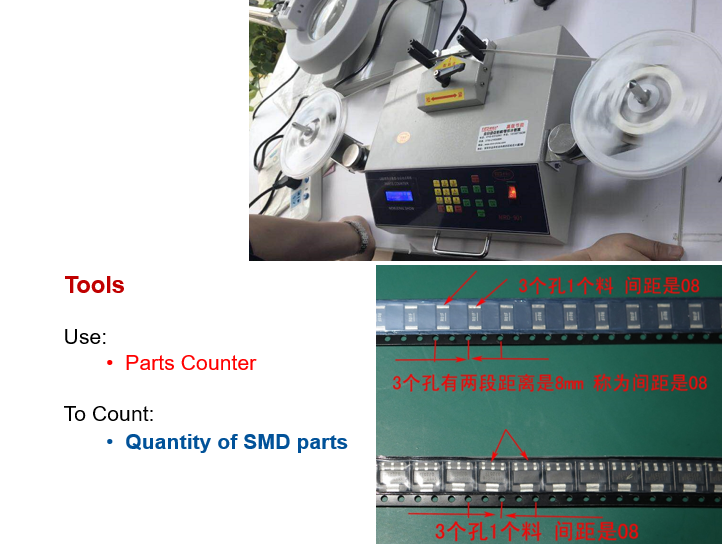

JSD collaborates closely with customers to understand their exact requirements and can fulfill orders for specified quantities of incomplete packaging.

JSD aim is to retain the original packaging whenever possible. However, if non-continuous strips, no reels, or tube stock is the only available option, we seek the customer’s approval before providing appropriate re-taping and re-reeling services. This is done to help customers adapt to SMT automated production processes. Additionally, for moisture-sensitive devices, we can offer vacuum packaging services that conform to the JEDEC industry standards.

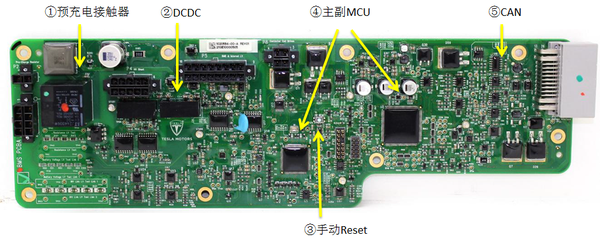

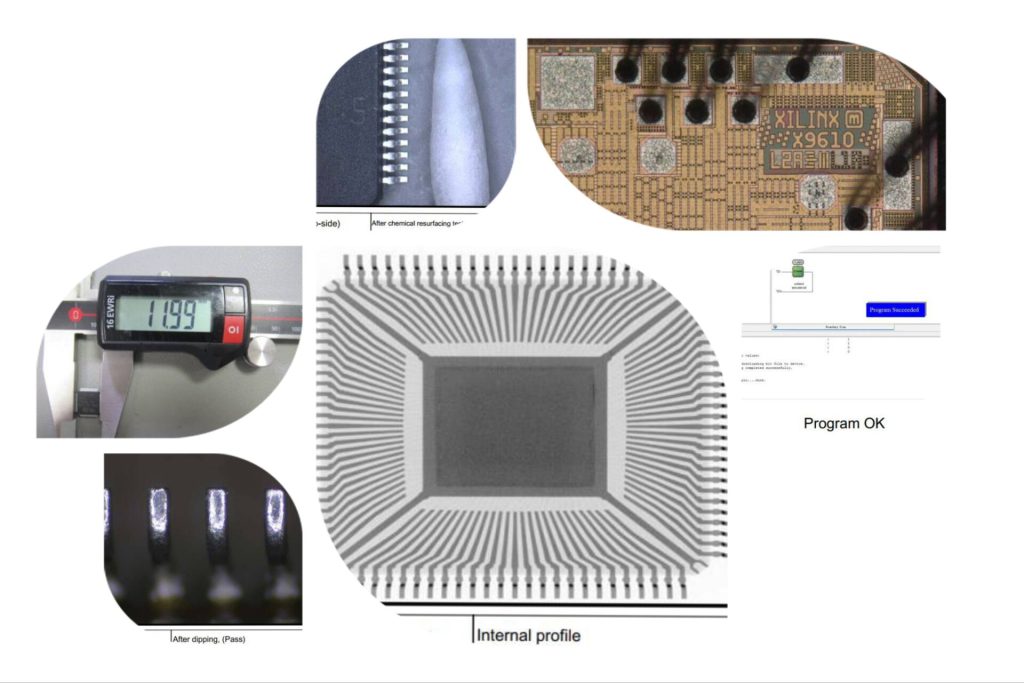

JSD offers a range of quality verification tests such as Solderability, IV, Electrical, External visual inspection, De-capsulation analysis, X-Ray internal structure comparison, and Hi/Lo temperature test. JSD can either arrange for a qualified third-party testing lab or comply with the customer’s instructions to use a specific one for conducting these tests. JSD aim is to ensure that our products meet the required quality standards, and we are committed to delivering the best possible customer experience.

In situations where a material shortage has no immediate solution, JSD’s team of experienced engineers, who possess in-depth knowledge of component parameters, can liaise seamlessly with suppliers to identify and recommend the most feasible alternative products.